What is Curing in Fruits?

What is Curing in Fruits?

Curing is a critical post-harvest management practice employed primarily to improve harvested fruits’ quality, flavor, and longevity. This process involves specific treatments designed to induce physiological and biochemical changes within the fruit, enhancing its storability and market appeal. At its core, curing aims to reduce respiration rates, moisture loss, and decay, ensuring that fruits retain their optimal characteristics during storage and transport.

There are several methods of curing,

- Air curing

- Controlled Environment Curing

Air curing

Air curing, as the name suggests, allows harvested fruits to be exposed to ambient air under well-ventilated conditions for a designated period. This technique is beneficial for fruits that are less sensitive to ambient conditions, allowing for natural drying and recovery from mechanical damage sustained during harvesting.

Controlled Environment Curing

In contrast, controlled environment curing takes place in specially designed chambers where temperature, humidity, and ventilation are precisely regulated. This method offers a more consistent and effective means of curing, as it can be tailored to the specific needs of various fruit types.

The physiological effects (PE) during the curing

The PE during the curing process is remarkable. For example, ethylene —a natural hormone production involved in ripening—increases during curing, promoting flavor development and enhancing the fruit’s sweetness and aroma. Curing also reduces the incidence of post-harvest diseases, consequently lowering waste and improving marketability. From a commercial grower’s perspective, effective curing practices can lead to longer shelf life and better price points in the market, while consumers benefit from improved taste and quality in the fruits they purchase. The significance of curing should not be underestimated; it plays an essential role in ensuring that fruits meet both consumer expectations and market standards.

The Science Behind Curing: Physiological Changes

Curing is a critical post-harvest treatment that initiates a series of biochemical and physiological changes in horticultural crops. This process, primarily focused on fruits and vegetables, helps to enhance their quality by affecting texture, taste, and nutritional composition. During curing, the plant’s natural enzymes and hormonal activities are activated, which leads to several transformations. For example, the breakdown of starches into simpler sugars enhances sweetness, making fruits like bananas and mangoes more palatable. Additionally, curing aids in the conversion of acidic compounds, impacting the overall flavor profile.

Furthermore, during the curing process, modifications in the fruit’s cell structure occur, including the softening of tissues. This response results in improved texture, making the fruit more appealing to consumers. In fruits such as tomatoes, curing contributes to the fruit’s juiciness, ultimately enhancing the eating experience. Nutritional aspects are also significantly impacted, as the curing can increase the availability of certain vitamins and antioxidants, thereby improving overall health benefits.

Environmental factors play a pivotal role in the efficiency of the curing process. The temperature is a primary determinant, as higher temperatures tend to accelerate enzyme activities, leading to quicker ripening. However, excessive heat can result in undesirable over-ripening. Ideal humidity levels are similarly important; they prevent excessive water loss, which can lead to shriveling. For instance, some fruits such as garlic and onions benefit from higher humidity during curing to retain moisture, while others like sweet potatoes require a drier environment to prevent rot.

Light exposure is another variable that can affect curing outcomes. Some studies indicate that specific wavelengths of light can influence the synthesis of phytonutrients. Understanding these environmental factors and their effects is essential for optimizing the curing process of various fruits and vegetables in horticultural practices.

Artificial Ripening (AR): Techniques and Technologies

AR plays an important part in modern agricultural practices, enabling the controlled maturation of horticultural produce to enhance marketability and reduce post-harvest losses. The necessity for AR arises from the need to synchronize the ripening process, ensuring that produce reaches optimal quality and flavor at the right time for sale and consumption. Throughout this process, various techniques and technologies have emerged, each with its advantages and challenges.

One of the most common methods of AR involves the use of ethylene gaseous hormone, that significantly influences fruit maturation. Ethylene can be applied in various forms, including gas, liquid formulations, or through ripening chambers specifically designed to maintain the optimal environment for the ethylene to induce ripening. These chambers often provide controlled temperature, humidity, and air circulation, which together enhance the efficacy of ethylene application.

In addition to ethylene, chemical accelerators are also employed to hasten the ripening process. Substances such as calcium carbide and certain plant growth regulators act as ripening agents but come with safety considerations. Their use can lead to concerns regarding the residues left on products and potential health impacts. Thus, while they can be effective in achieving quicker ripening, careful attention must be paid to safety standards and consumer preferences.

Despite its various benefits, artificial ripening may lead to potential drawbacks. For instance, over-reliance on these methods can sometimes result in fruit that lacks the natural flavor and texture associated with organic ripening. Additionally, the quality of artificially ripened fruits can vary, impacting consumer satisfaction. Case studies in horticultural crops like bananas, mangoes, and tomatoes illustrate the practical application of these techniques, showcasing how artificial ripening can effectively enhance income while raising questions about optimal practices. Further exploration of these methods will contribute to understanding and improving the quality standards in horticulture.

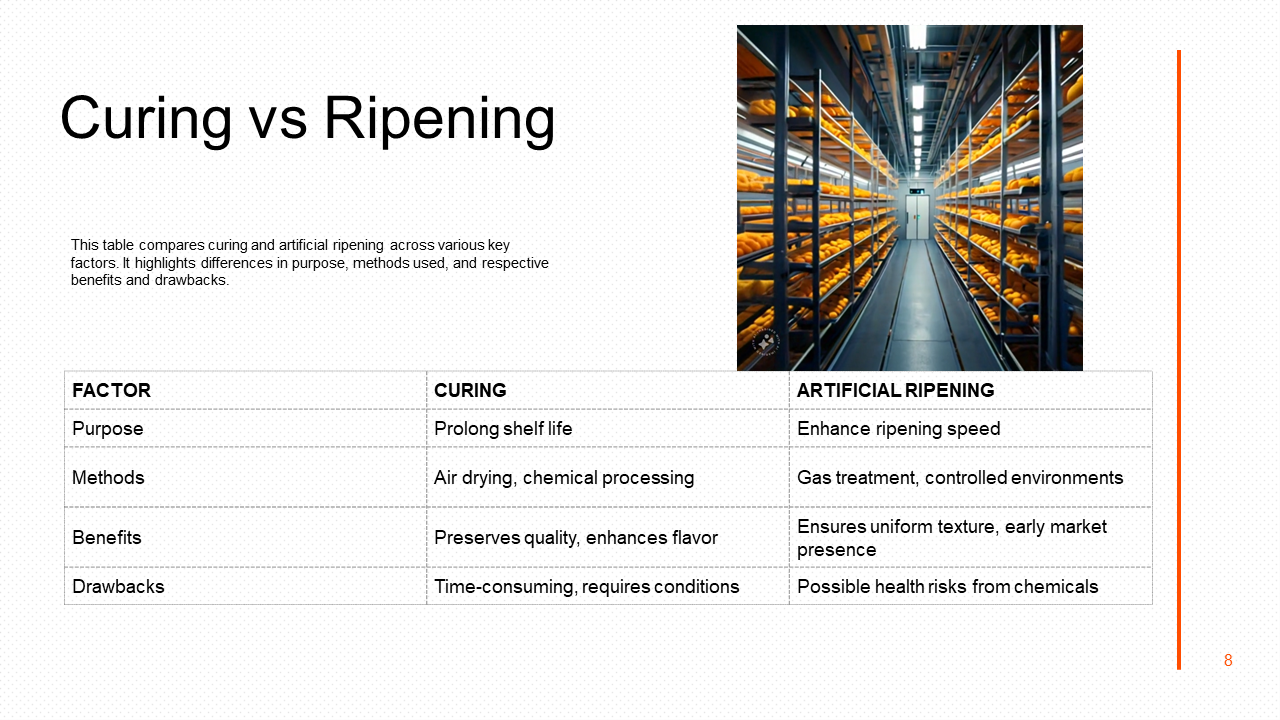

Comparison: Curing vs. Artificial Ripening

Curing and artificial ripening are two distinct processes employed in the horticultural sector to enhance the quality and shelf life of fruits and vegetables. Both methods aim to optimize the marketability of produce, yet they operate through different mechanisms and serve unique purposes. Curing primarily focuses on the natural processes that occur post-harvest, allowing fruits and vegetables to develop their flavors, textures, and nutritional profiles. This method often involves the use of controlled environments to reduce moisture content, promote healing from harvesting damage, and enhance overall fruit longevity. Commonly, crops such as onions, garlic, and squash utilize curing to improve their storage life.

In contrast, artificial ripening primarily facilitates the acceleration of the ripening process, frequently employing chemicals like ethylene or ethylene-releasing agents to trigger maturation. This method is commonly applied to fruits such as bananas, mangoes, and tomatoes, allowing them to reach an optimal ripeness quickly, thereby catering to consumer demand for ready-to-eat produce. While both methods seek to improve fruit quality and extend shelf life, their influence on flavor and texture can differ significantly. Curing often enhances the natural attributes of the produce, while artificial ripening may sometimes lead to discrepancies in taste and texture if not meticulously monitored.

Comparison of curing artificial ripening and coating on Horticultural Produce

Consumer perspectives also play a crucial role in shaping the acceptance of these processes. Many consumers prefer traditionally cured products believing they offer enhanced flavors and overall quality. In contrast, there can be skepticism regarding artificially ripened produce, particularly concerning perceived health implications. Consequently, best practices for maintaining fruit quality throughout the supply chain should prioritize transparency and education. By clarifying the differences and benefits of these methods, stakeholders can better inform purchasing decisions and promote the highest standards in horticultural production, ultimately ensuring quality yields that satisfy consumer expectations.

ha

ha

Understanding Modified Atmosphere Packaging for Fruits and Vegetables

Danish Khana

Excellent